Comparing the effects of recycling tires to those of utilizing new materials to make the same product, an ongoing study demonstrates that recycling tires prevents harmful emissions.

For information on eTracks’ tire recycling initiatives, view the most recent LCA Report: Scrap Tire Life Cycle Assessment (updated to include 2023 data).

Fulfilling producer obligations under Ontario’s Resource Recovery and Circular Economy Act (RRCEA) and Tire Regulation 225/18 entails offering services to producers that guarantee they reach their legal goal of collecting and recycling all used tires they sell as Tire Derived Product (TDP). The more traditional usage of new, or “raw” resources to create things is replaced by a TDP.

Compared to the use of (new) resources they replace, consumers anticipate that items created from recycled tires will have a positive environmental impact. In order to quantify this expectation, seven members of the Canadian Association of Tire Recycling Agencies (CATRA) voluntarily participated in the benchmark study known as the “Scrap Tire Life Cycle Assessment (LCA)”. Participating tire recycling agencies’ data from 2019-2023 is gathered and analyzed for the current project, and participants receive an updated individual LCA report annually. A critical review panel’s involvement guaranteed that the reporting and analysis technique complied with the International Organization for Standardization (ISO 14044) standards.

What is an ISO Critical Review?

Following ISO guidelines, the LCA report was subjected to a critical review procedure. A critical review’s goal is to make sure that research is conducted in accordance with ISO methodology and best practices and that the data included in a report supports its conclusions. According to the LCA assessment, the report complied with ISO criteria, the techniques employed to conduct the LCA were deemed scientifically sound, and the evidence provided supported the conclusions.

Note: the provincial model and findings for Ontario were included in the scope of the critical review, the individual provincial report was not.

The following summary of the life cycle assessment focuses on data provided by eTracks Tire Management Systems for its 2023 tire recycling activities in Ontario including: used tire collection, hauling, processing, and repurposing activities.

Study Overview of Results from 2019-2023

By preventing emissions, recovering resources, and promoting a decreased reliance on raw materials, eTracks’ operations in 2023 significantly improved the environment. The avoided impacts are measured using globally accepted units of measurement across seven major environmental categories. Where possible, real-world equivalents are given to help illustrate these results.

Global warming (climate change), smog creation, human health particulates, acidification, ozone depletion, eutrophication, and blue water depletion are the seven environmental consequences examined by the LCA study. The findings illustrate how a TDP performs in each of these areas in relation to the life cycle effects of the displaced material in question. The findings also illustrate the ecological effect comparisons between each TDP. In Ontario, the avoided impacts for each of these ecological impacts were far larger than the ones when new materials were utilized; the scores for climate change, eutrophication, acidification, and human health particles were very beneficial.

The study’s seven impact categories calculated the emissions resulting from tire recycling operations in relation to the emissions that would have been produced in 2023 if the same TDP had been made using new or raw materials.

(Numbers have been rounded up or down as appropriate.)

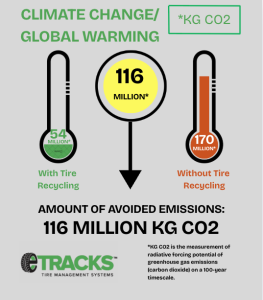

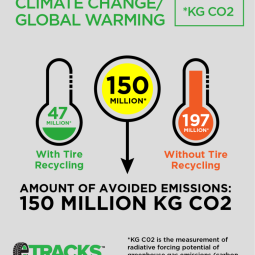

Climate Change/Global Warming (kg CO2)

Indicates the radiative forcing potential of greenhouse gas emissions (carbon dioxide) on a 100-year timescale. The avoided impacts in this category are equivalent to avoiding 342 million km driven in private vehicles.

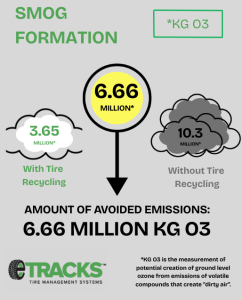

Smog Formation (kg O3)

Indicates the potential creation of ground level ozone from emissions of volatile compounds that create “dirty air”. The avoided impacts in this category are equivalent to avoiding 3.66 million hours of diesel loader operation.

Human Health-Particulates (kg PM2.5)

Indicates the quantity of particulate matter released into the air, adjusted for severity by comparison to 2.5-micron dust. These particles cannot be seen by the human eye, but can be inhaled. Avoided emissions in this category are equivalent to avoiding the burning of 76.7 million kg of coal.

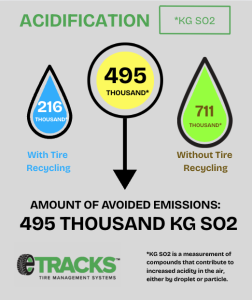

Acidification (kg SO2)

Reports emission of compounds that contribute to increased acidity in the air, either by droplet or particle. Avoided emissions in this category are equivalent to avoiding enough acid rain to fill 6.5 average in-ground backyard pools.

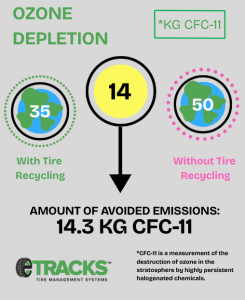

Ozone Depletion (kg CFC-11)

Describes the destruction of ozone in the stratosphere by highly persistent halogenated chemicals. Avoided emissions in this category are equivalent to avoiding CO2 emissions from 42 roundtrip flights from Toronto, ON to London, ENG.

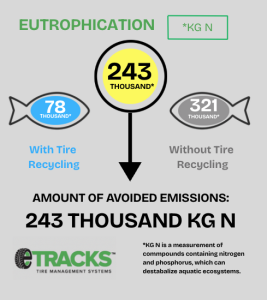

Eutrophication (kg N)

Reports environmental emissions of compounds containing nitrogen and phosphorus, which can destabilize aquatic ecosystems. The avoided emissions in this category protected 4,860 km² of freshwater ecosystems from being oxygen starved, which is approximately 25% of Lake Ontario.

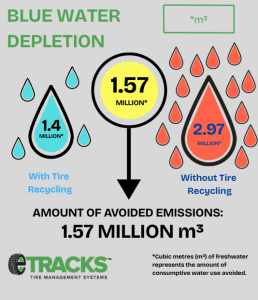

Blue Water Depletion (m3)

Cubic metres of freshwater represents the amount of consumptive water use avoided, mainly due to recycled steel displacing virgin steel production. Avoided impacts in this category are equivalent to saving the amount of water used for 24.1 million average showers.

Source: Scrap Tire Recovery and Recycling in Ontario, 2019–2023. CATRA 2021 Scrap Tire Life Cycle Assessment Year-over-year update 2024-1

Circular Economy and Tire Recycling

These avoided impacts are the result of a circular approach to materials management, which includes efficient tire recycling practices, reduced landfill use, and the recovery of valuable resources such as steel and rubber. The Material Circularity Index (MCI) is a metric developed by the Ellen MacArthur Foundation to measure how effectively a product or system utilizes materials in use and minimizes waste, by circular economy principles. The MCI for eTracks’ tire-derived products remained moderate to high at 0.58, reflecting strong circular economy performance.

We utilize our resources in a way that extends their lifespan, decreases waste, and innovates to prolong the life cycle of the materials and goods we use on a daily basis. In order to maintain the sustainability of our economy, we must all actively participate—consumers, business executives, and the government—and collaborate to create plans for boosting the sustainability of our systems.

The Products Most Effective in Reducing Emissions

Reusing and retreading used tires, crumb rubber (containing fibre and acrylic sand), rubberized asphalt, moulded rubber, moulded concrete, and blast mats are among the products that have had the greatest impact on emission reductions in Ontario. We recycled more end-of-life tires in Ontario than were produced, particularly when it came to making more valuable products like asphalt and crumb rubber for moulded items. Comparing the LCA data from 2019-2022, environmental efficiency in 2023 remained high despite variations in collection and processing volumes.

“With a regulatory target of 100% tire collection and recycling, Ontarian’s benefit from Extended Producer Responsibility (EPR); the reduction in emissions shown in this study are proof of that. The broader challenge for industry players is to improve our technologies and recycling systems, such that it’s easy and practical to repurpose materials, instead of sourcing new materials. Ontario continues to move towards sustainable goals and we’re excited to be a part of that – building better recycling systems, removing valuable materials from waste streams and putting them back into use for as long as possible,” says Steve Meldrum, CEO, eTracks Tire Management Systems.

Results Inform Decisions

eTracks is a private company that offers services to Ontario tire producers by assisting them in meeting or exceeding their regulatory obligations to collect, recycle and repurpose the used tires they sell into the marketplace. With this confirmed understanding, eTracks and its clients can show the benefits of recycling and repurposing programs to successfully lessen adverse environmental effects. Along with many other considerations that go into planning, decision-making, and fulfilling compliance duties, the study’s findings also encourage us to think about the ecological ramifications.

Study Background

In order to provide a boundary for analysis around end-of-life tire management systems that start when worn tires are first brought back to a tire collecting point (such as tire shops), California-based Scope 3 Consulting LLC created the study. The effects of shipping the tires and turning them into a TDP are contrasted with those of manufacturing traditional non-tire-derived goods. The assignment of quantitative ecological impacts for the life cycle of each TDP and its corresponding displaced product was done using widely recognized industry data sources. These impacts are computed up until the material is prepared for distribution to its end-use. This is known as “approved use” and “recovery” in Ontario. It is the process of turning a used tire into a new product, including playground flooring, cattle mats, or concrete and asphalt that has been rubberized. The Ontario study combines information from the Resource Productivity & Recovery Authority (RPRA)(2019), the Ontario Tire Stewardship (OTS) archives (2017-2018), and eTracks Tire Management Systems (2020).

If you have questions about the Ontario report, please contact Melissa Carlaw, Director of Communications and Marketing at mcarlaw@etracks.ca.

More information summarizing the results achieved by participating CATRA members will be shared on the CATRA website in the coming weeks.

About eTracks: eTracks was incorporated under the Canada Not-For-Profit Corporations Act in 2017 and is governed by an independent Board of Directors. The company was originally created by the Tire and Rubber Association of Canada (TRAC) to meet the needs of TRAC members and other obligated tire producers under the Resource Recovery and Circular Economy Act (RRCEA) in Ontario. Since then, eTracks has helped shape Ontario’s recycling industry to become known as a trusted, innovative, industry leader in Ontario’s circular economy. Our purpose as a Producer Responsibility Organization (PRO), and one we are proud of, is our commitment to managing recyclable materials, and corresponding supply chains in a responsible, reliable and fair manner. eTracks has the experience and the ability to support other materials classes as they transition to individual or extended producer responsibility models, supporting systems in moving from waste to resource models to create a more circular economy for future generations.

Circular economy , climate change , emissions , EPR , IPR , Ontario , Producer Responsibility Organization , recycling , repurpose , RRCEA , tire recycling